Carbonium® is a new generation of material entirely sourced from the French aerospace transformation sector.

Composed of two thirds of intermediate modulus carbon fiber and one third of high temperature epoxy, Carbonium® brings its structural properties and a totally unique aesthetic to the parts obtained.

7 micron carbon filaments reflect light dynamically to bring matter to life

Carbon is a fiber 3 times stiffer than titanium for a weight 2 times lower.

The selection of raw materials makes it possible to significantly reduce the CO2 emissions of the product.

By adapting the characteristics of the material and the transformation process used, Lavoisier Composites can customize the rendering and fully control the structural properties obtained.

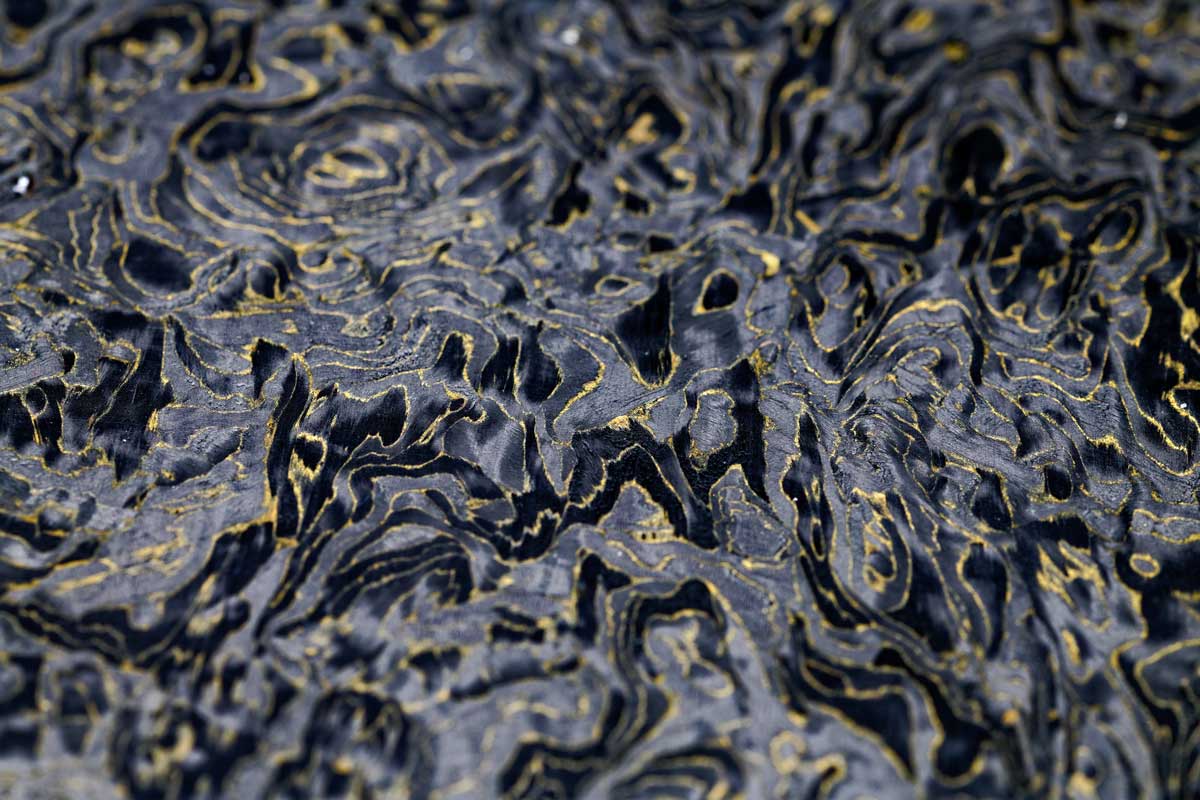

The unique beauty of carbon is brought out when combined with precious metals. This is the challenge that Lavoisier Composites has taken by intimately marrying carbon and gold to obtain Carbonium® Gold.

Unlike a superficial decor, the gold and carbon fusion process gives Carbonium® Gold a completely new organic dimension.

As with a precious walnut burl, each piece of Carbonium® Gold reveals a golden grain whose singularity and finesse are unique.

Other precious metals such as silver and platinum version are under development.

Thanks to a very high-pressure molding and a specific finishing operation, Carbonium® Original gives the resulting pieces a dark and deep aesthetic rendering that selectively polarises the incident light to reflect it in a dynamic manner.

Carbonium® Original is the genuine expression of carbon fibre that light sublimates for our wonder.

It is in full sun or in the light of a projector that a piece of Carbonium® Original truly takes life. It's a complete experience that no photo can replace.

To contrast differently with the black depth of the carbon fiber, color versions are also available on request.

In combination with a range of selected mineral pigments, it will be possible to imagine countless variations of Carbonium® with colored grain. The red and the black is certainly a perfect match but many other colors are available on demand.

Carbonium® Structure is the eco-sourced material that combines the best cost / performance ratio. Intended for the compression molding process (also called "thermo-compression"), this material has all the necessary characteristics to manufacture structural parts in series. It is obtained from a pre-impregnated carbon / epoxy designed to make some of the vital parts of the structure of the latest generations of civil commercial aircrafts.

The length of the carbon fibers as well as the fiber / resin ratio provide this material with optimum molding and machining characteristics

The particular architecture formed by the carbon fiber bundles combined with a 180 °C class epoxy provides high impact tolerance

Compared with equivalent materials on the market, the material reduces the carbon footprint by 13 kg per kg of material used

With its high fiber volume ratio, Carbonium® Structure has an ideal strength / stiffness profile while being 40% lighter than aluminum. The manufacturing method used offers the unique ability to control the fiber length to maximize the mechanical properties of the part obtained without compromising its ability to be press-molded under good conditions.

Even though the fineness of carbon filaments of 7 micrometers brings its particular aesthetic, it is above all for its specific mechanical properties that carbon fiber has become essential in the aeronautical sector. The use of long fibers and their optimal implementation are some of the secrets of a structural composite material.

Developed according to a process that has been the subject of 3 patents, Cabonium® Structure is intended for the most demanding applications requiring high mechanical properties.

© 2025 - Lavoisier Composites — Created by Maxime Emorine